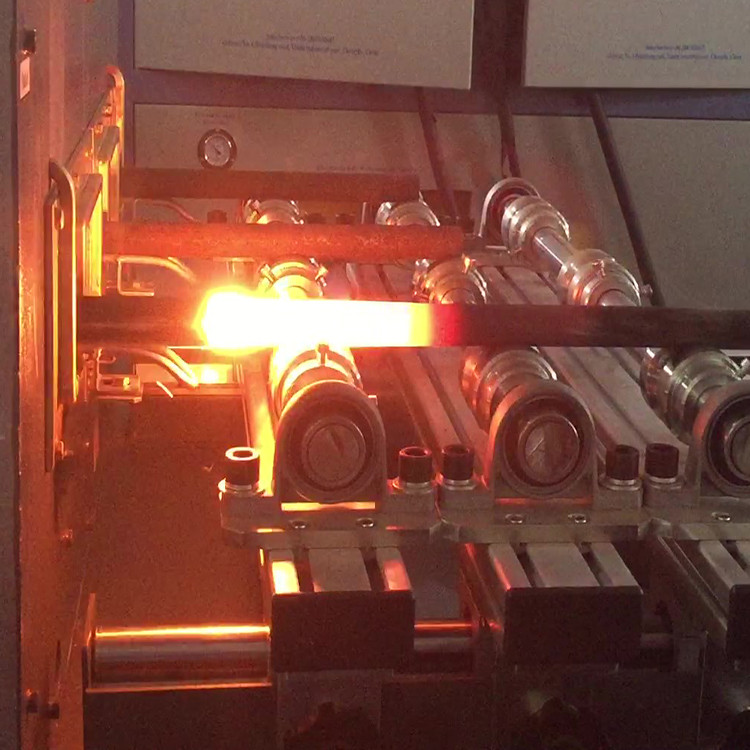

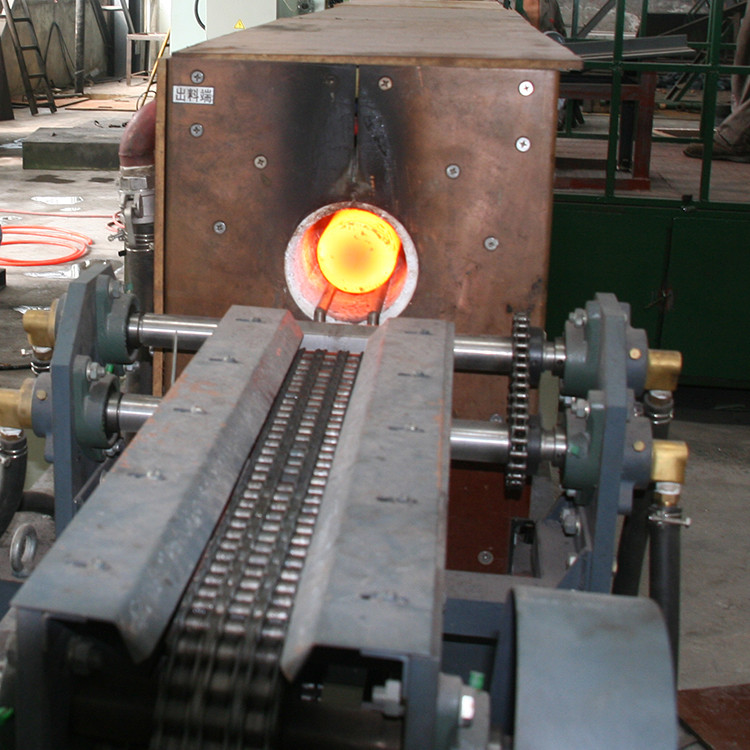

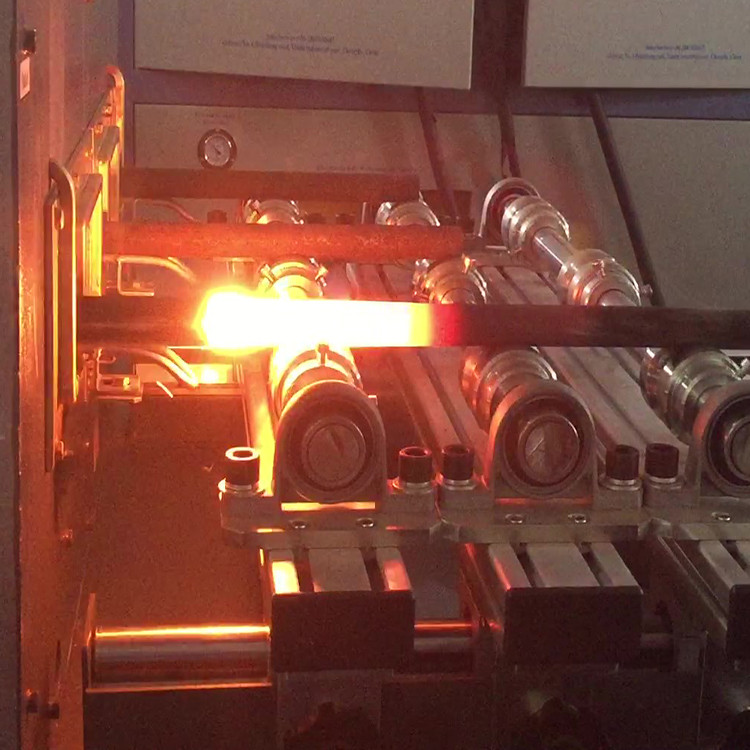

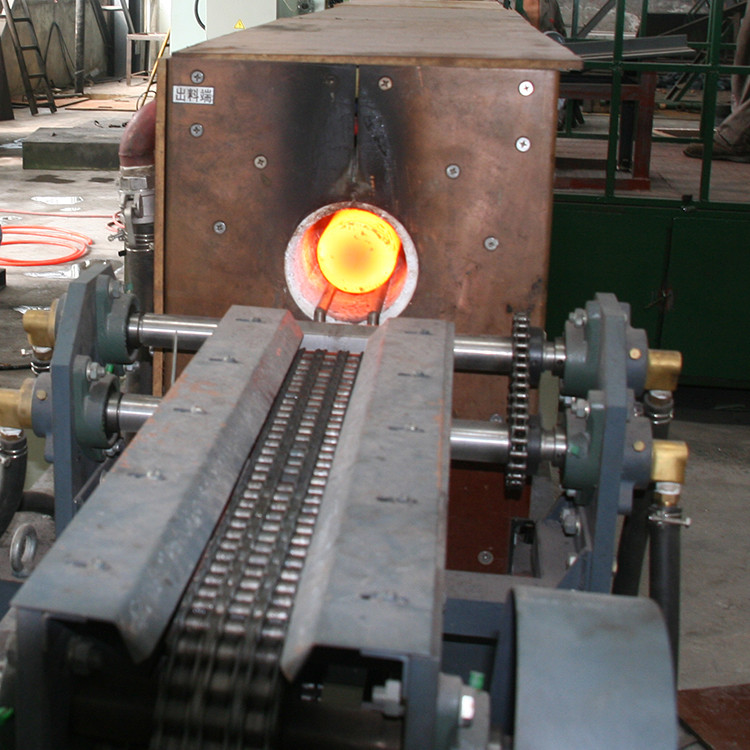

Induction heating equipment for heat transfer is the process of placing a workpiece into an intermediate frequency furnace inductor, and during the heating process, the intermediate frequency furnace heat transfer makes the internal and surface temperatures of the entire workpiece roughly equal. Induction heating equipment with medium frequency furnaces can use induction heating power sources of different frequencies to heat workpieces according to the geometric shape and heating process requirements of different materials. The heating of metal materials before forging, extrusion, hot rolling, and shearing, as well as the overall heat treatment of metal materials such as quenching, annealing, and tempering, can all be achieved through induction heating equipment. The picture shows our company using a heating furnace for casting processing on site.

Induction heating equipment is used to heat the workpiece by placing it inside an intermediate frequency furnace inductor. During the heating process, the intermediate frequency furnace heats up the interior and surface temperature of the entire workpiece

The process of equality. Induction heating equipment can use induction heating power sources of different frequencies to heat workpieces according to the geometric shape and heating process requirements of different materials. The heating of metal materials before forging, extrusion, hot rolling, and shearing, as well as the overall heat treatment of metal materials such as quenching, annealing, and tempering, can all be achieved through induction heating equipment.